The Mixed Flow Pump, or Combined Flow Pump generates it's head through a combination of both axial and radial forces, and can be defined as pump impeller design with specific speeds between 4,200 and 9,000 (US Units). The Mixed Flow impeller inlet diameter differs from the disharge diameter with varying vane angles and radial velocities. Standard Morrison Mixed Flow Pump models have hydraulic coverage between approx. 2,000 GPM and 250,000 GPM capacities, with total heads between 25 and 75 feet of water.

The High-Efficiency Morrison Mixed Flow Lineshaft Pump has been engineered and manufactured for severe duty applications and continuous operation.

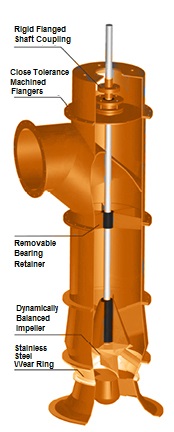

Morrison Mixed Flow Pumps include all standard features of our lineshaft pumps including jointed (segmented) pump construction, dynamic balancing of impellers, stainless steel rotating elements and wear rings, electrical isolation of dissimilar metals, removable bearing retainers, and standard marine nitrile rubber radial bearings. Furthermore, all Morrison Mixed Flow Pumps are provided with certified pump performance curves. Morrison High-Efficiency Mixed Flow Lineshaft Pumps can be in vertical, horizontal, or slant (angle) configurations, and may be oil, water, or product lubricated (no seals, no oil).

The Morrison Pump Company is committed to designing and manufacturing the most innovative, highest quality pumping equipment available. Morrison Pump Company is a worldwide technical leader in the design and manufacturing of high capacity water pumps, specialty and flood control pump systems.